Everything about Plasgad’s pallets

Plastic pallets play an important role in storage, shipping and delivery processes, so it is essential to chose a pallet that fully meets your requirements. We have created this guide to help you make an informed choice from the broad variety of pallets with different features:

International standards for pallets dimensions

- The 1,200 X 800 mm pallets are mostly used in the European market.

- The 1,100 X 1,100 mm pallets are mostly used in the Asian markets (the equivalent American dimensions are 43 X 43 inch).

- The 1,200 X 1,000 mm pallets are used worldwide (the equivalent American dimensions are 40 X 48 inch).

- Half pallet – 800 X 600 mm pallet, widely used by retail chains and for shipping high-value goods in small packages.

- Quarter pallet – a 600 X 400 mm pallet, another option popular with retail chains and for shipping high-value goods in small packages.

Nesting and storage

The term ‘nesting’ refers to the ability of one pallet to fit into the pallet underneath it, a feature that saves you a lot of storage space. Nesting capability is measured by ‘space saving ratio’ – with higher ratio indicating greater space savings.

How does it work?

A space saving ratio of 70% means that when nested, 70% of the pallet’s height fits into the pallet underneath, so that the pallet will only take up 30% of the storage space it would otherwise have required.

The pallet’s structure

The pallet’s feet

Every pallet is elevated either by feet or by skids. Full-size pallets have 9 feet. In most types of pallets, the feet are designed to enable pallets to nest on top of each other, making pallets with feet an excellent space-saving solution for shipping and storage.

Did you know?

A column of nested pallets can save up to 80% of the total height of the pallets!

Skids

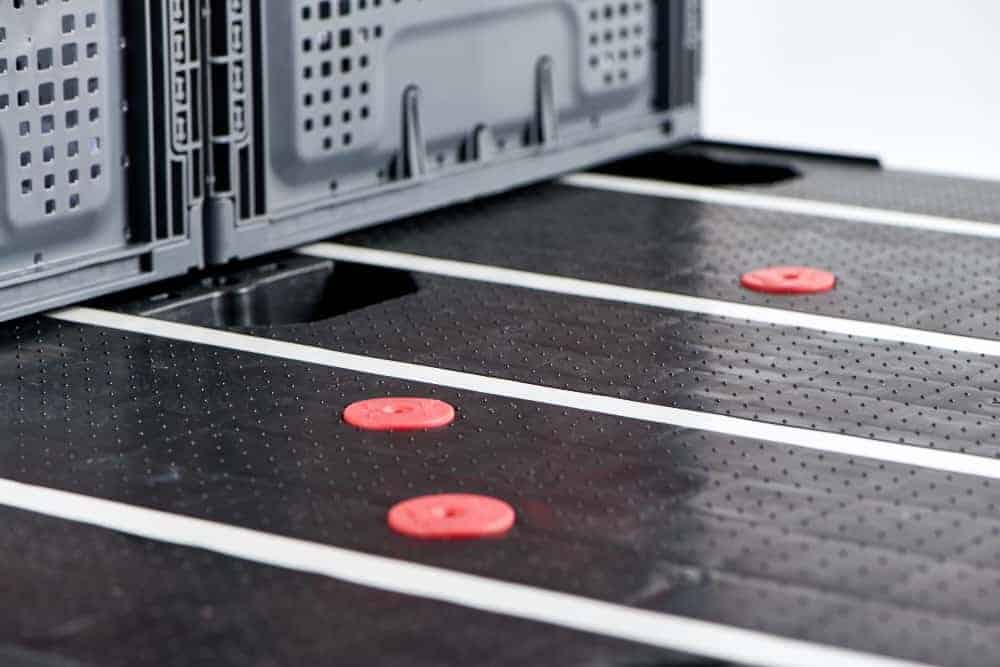

Skids are beams that connect the pallet’s feet to each other. Pallets can have between three and six skids, but the most common configuration is 3 parallel skids across the pallet.

Skids offer many advantages that extend the functionality of the pallet:

- They make the pallet more sturdy and durable.

- They make racking possible.

- They are ideal for automated systems.

- The enable stacking of goods.

Pallets designed for heavy and medium loads will usually have built-in skids. These pallets are placed on top of each other and cannot be nested. If you require a solution that offers both the ability to rack or stack goods as well as efficient, space-saving storage capability, you may consider pallets with snap-on skids. These skids are packed separately from the pallet and assembled at the customer’s site. This solution combines the advantages of skids with significant space and cost savings.

The pallet’s deck

- The deck of the pallet is its top surface, on which the goods are placed.

- The deck can be solid or ventilated.

- Ventilated decks have the advantage of being lightweight and cost-effective.

- Solid decks offer greater sturdiness and help keep the goods clean.

- The deck’s characteristics can be adjusted to the customer’s requirements.

Load capacity

When choosing a pallet, one of the most important parameters is its maximum load capacity. Maximum load capacity is tested in three working modes: static, dynamic and racking.

Static load

This is the maximum weight that can be loaded on the deck when the pallet is placed on a flat floor. This mode will have a higher load capacity than the two other modes. When pallets are stacked, the static load refers to the total weight loaded onto the bottom pallet.

Dynamic load

This refers to the weight of the goods (load) placed on the deck while the pallet is being lifted by a forklift. In this mode it is important to consider how goods are packed and how their weight is distributed across the surface of the pallet. To maximize the load capacity, it is recommended to pack the goods in such a way that their weight is distributed evenly across the deck. The best way to do this is to cross-stack the crates and to use stretch wrap to secure them.

Racking

The term “Racking” refers to using pallets not just for shipping, but for storage as well. The racking system is a robust structure made of steel beams, with several levels on which pallets can be stored. This method provides high per-area storage capacity. The pallet is placed on two parallel beams. Pallets designed for racking must be exceptionally strong and durable, to prevent them from bending under the heavy load. To enhance pallets’ racking capacity, iron bars can be inserted into its plastic framework. The pallets most suitable for racking are pallets with skids.

Protecting the goods

Pallets must support the goods to prevent them from slipping off during shipping, storage and delivery. We have developed a number of features to help secure the goods and prevent them from falling off.

Safety rims

The pallets with safety rims have elevated edges that prevent goods from slipping off the deck. Safety rims are also useful for stacking pallets on top of each other. They prevent the pallets from sliding and help maintain the stability of the column during shipping and storage.

Textured surface

Small bumps are added to the top of the deck to give it a textured surface. These bumps increase the friction between the pallet and the goods, thereby reducing the movement of items placed on the deck.

Welded anti-slip strips

These elastic friction strips that are welded to the pallet’s deck to help prevent goods from slipping.

Rubber caps (“Gems”)

Rubber caps can be inserted into the deck to increase friction, both between the goods and the pallet and between the pallet and the forks of the forklift. This solution offers maximum protection against slipping, especially for dynamic working conditions.

Fastening goods using bands or stretch wrap

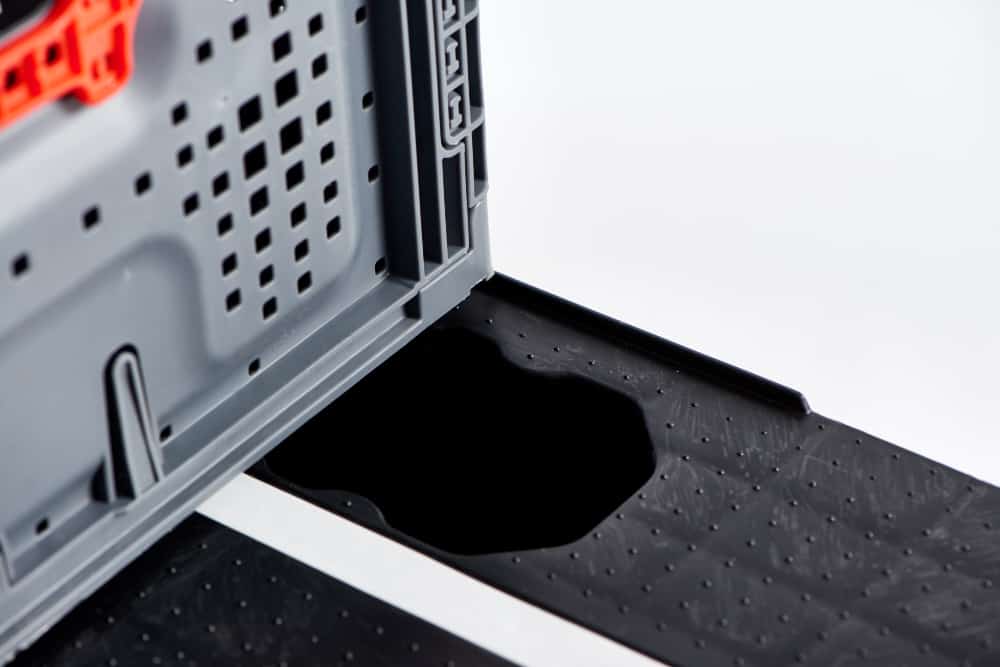

Fastening goods to the deck with a band or stretch wrap helps improve the distribution of the load across the deck and keeps the goods secured. Our pallets have a unique element that enables you to quickly fasten the edges of the stretch wrap to the pallet. All the pallets have recessed edges, to help securing band straps and prevent them from moving.

Shipping and handling the pallets

To make pallets ergonomic and easy to handle, they must be standards-compliant for handling by forklifts and automated systems.

Forklift access

We ensure that there is adequate space between the pallet’s deck and the floor and between the pallet’s feet. This way it is easy for a forklift operator to insert the forks under the pallet. Pallets with skids allow easy forklift access and are compatible with pallet jacks, thanks to the skids’ low height and the facets installed along its sides. When pallets are nested in a stack, the facet at the bottom of the deck makes it possible to easily lift a single pallet from the column using a forklift.

Processing by automated systems

When the pallets are expected to be processed by automated systems, the pallets’ properties must be customized accordingly. We can adjust the skids and the deck to meet the requirements of various automated systems, racking capabilities and automatic pallet separators.

Recycling and reusing pallets

Plasgad’s plastic pallets are manufactured from the best available raw materials, using cutting-edge technology. All our products are recyclable and are therefore especially cost-effective.

Reuse

Our pallets are exceptionally durable, they retain their quality, sturdiness and durability over time and can be reused over and over again. The pallets can be easily washed and cleaned.

Recycling

When pallets are no longer needed, you may send them to recycling facilities in your area. Alternatively, you can resell your used products to Plasgad, and we will recycle them using an advanced, environmentally-friendly process. By doing this you can save money as well as protect the environment.